Why Are Pickleball Paddles So Expensive?

Table of Contents

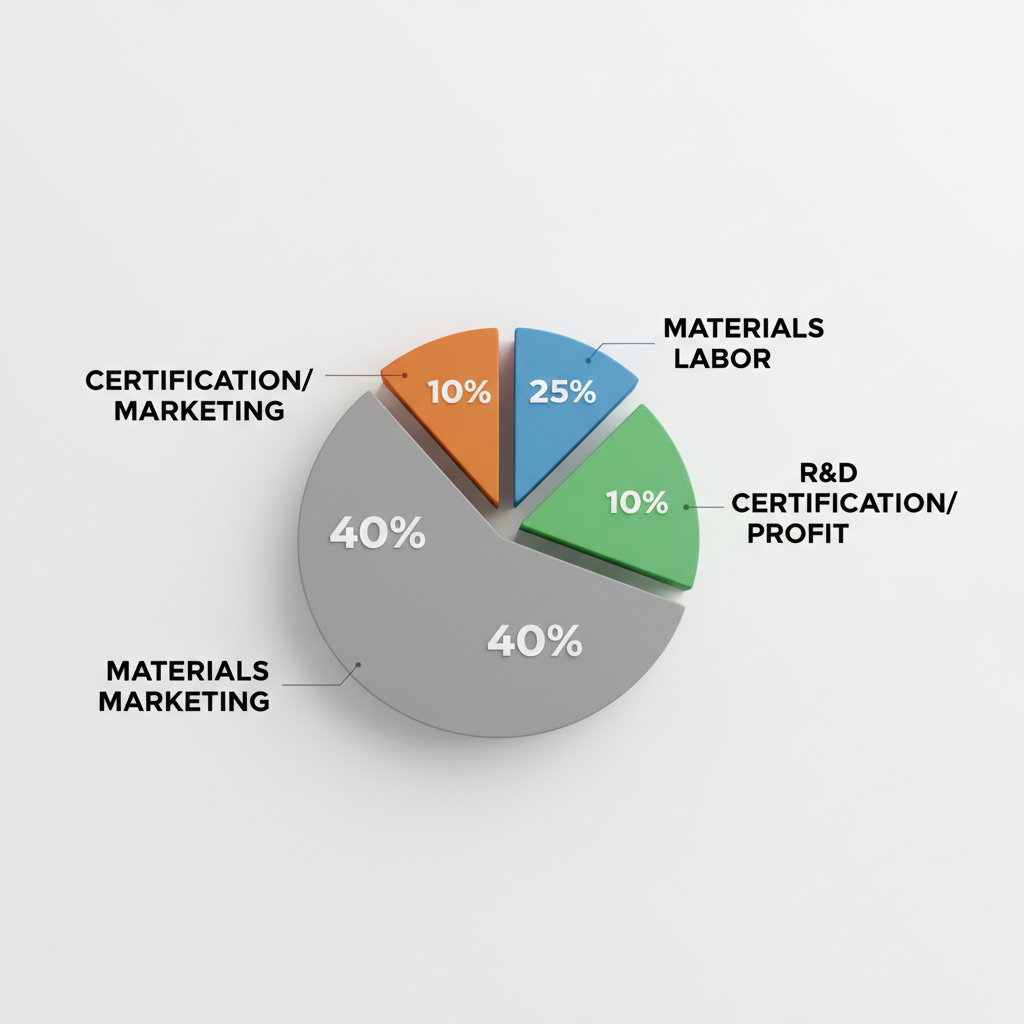

You have likely stared at a price tag exceeding $180 and wondered if the retailer added an extra zero by mistake, especially when the rack next to it holds $30 options. The reality is that the high cost of a premium pickleball paddle is driven by a convergence of aerospace-grade materials, labor-intensive thermoforming processes, and expensive certification mandates that cheap knockoffs simply bypass. For business owners and serious players alike, understanding these hidden cost drivers is the only way to distinguish between marketing fluff and genuine engineering value that prevents injury and enhances play.

What Materials Make Pickleball Paddles Costly?

The primary baseline for the price of any pickleball paddle is strictly dictated by the quality of the raw composite fibers and polymer cores used in its creation. Unlike basic wood or cheap plastic composites, high-performance paddles utilize certified materials that are difficult to source and expensive to process.

The Role of Kevlar and Carbon Fiber

You might be wondering if the specific type of carbon fiber actually impacts the manufacturing bill. Here is the deal: generic graphite is cheap and brittle, while authentic Toray T700 carbon fiber is an aerospace material that costs significantly more but offers unmatched tensile strength.

- Toray T700 Carbon: Imported Japanese fiber known for consistency.

- Kevlar/Aramid: Extremely difficult to cut, increasing labor time.

- Resin Systems: High-grade epoxies prevent delamination but cost 3x more.

Key Takeaway: Material Costs vs Performance

Raw inputs set a hard price floor that no amount of efficiency can remove.

| Material Grade | Relative Cost | Durability |

|---|---|---|

| Wood/Glass | Low | Low |

| Generic Carbon | Medium | Medium |

| Toray T700/Kevlar | High | Very High |

Switching from standard fiberglass to premium carbon fiber triples the raw material expenditure before labor is even applied.

How Does Construction Influence Price?

The method used to assemble a pickleball paddle shifts the cost dramatically, as modern thermoforming requires hours of precision labor compared to the minutes needed for cold-pressing. Cheap paddles are glued together like a sandwich, whereas high-end models are fused under immense heat and pressure.

Manufacturing Techniques: Precision Drives Price

You better believe that the difference between a $50 and a $250 paddle is often found in the “baking” process. Thermoforming involves placing the entire layup into a mold at high temperatures, creating a unibody structure that is far stronger but prone to higher defect rates during production.

- Cold Press: Fast, cheap, prone to dead spots.

- Thermoforming: Slow, expensive, creates a consistent sweet spot.

- Edge Foam Injection: Adds stability but requires manual injection steps.

Key Takeaway: Production Complexity

Labor hours and reject rates significantly spike the final MSRP.

| Method | Production Time | Defect Risk |

|---|---|---|

| Cold Press | 20 Mins | Low |

| Hot Press | 45 Mins | Medium |

| Thermoformed | 2-3 Hours | High |

Thermoforming requires 4x the production time of cold pressing, justifying a significantly higher wholesale and retail price point.

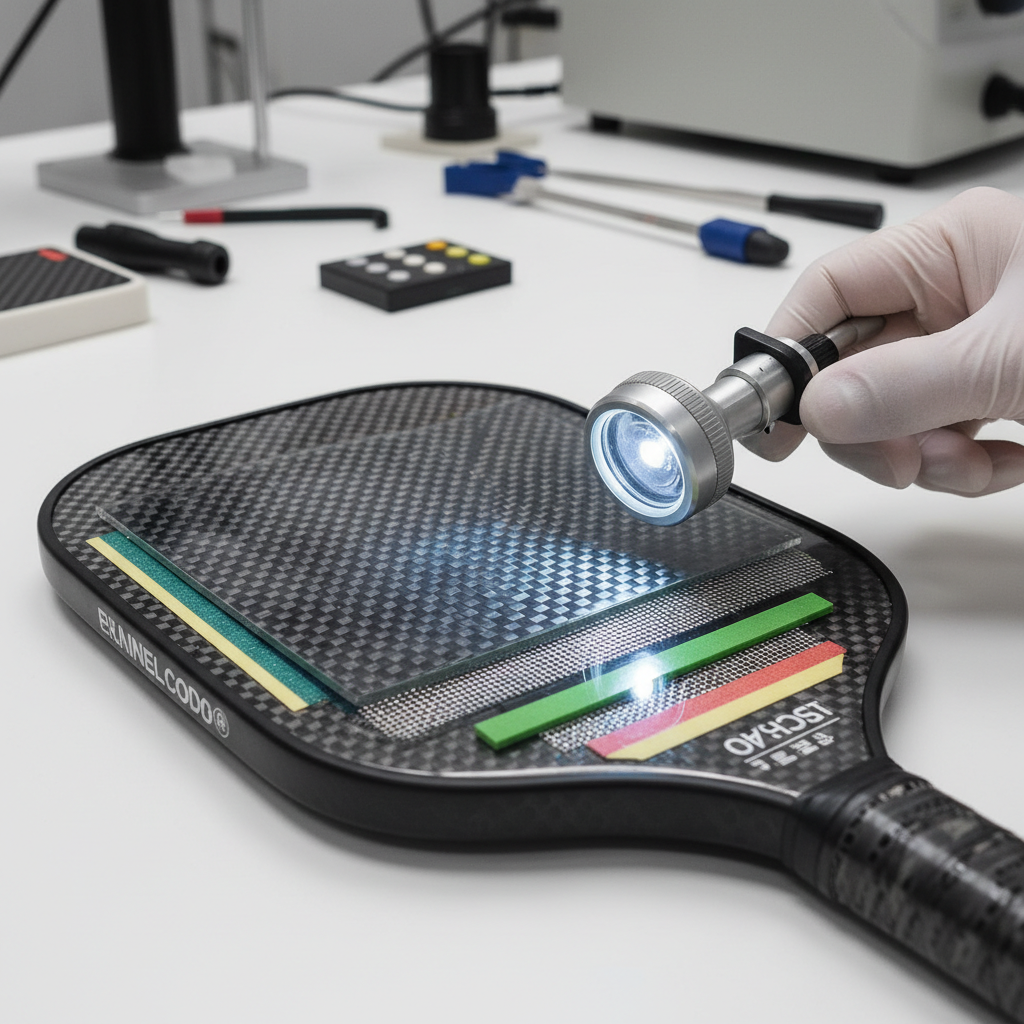

Why Is R&D Critical for New Pickleball Paddle Tech?

Before a single unit is sold, manufacturers burn through massive capital developing the geometry and swing weight of a new pickleball paddle to ensure it performs at a pro level. This phase is the hidden tax on innovation, covering the salaries of engineers and the cost of prototyping molds that may never be used.

Testing Layups and Prototyping

What’s the catch? You cannot just guess the perfect balance point; you have to build it, test it, and often destroy it. Engineers test hundreds of layup variations—changing fiber orientation by single degrees—to find the optimal blend of power and control.

- Destructive Testing: Breaking paddles to find failure points.

- Mold Costs: Each experimental shape requires a custom metal mold.

- Player Feedback: Shipping prototypes to pros for real-world validation.

Key Takeaway: The Price of Innovation

Innovation is expensive, but stagnation is fatal in this market.

| R&D Stage | Cost Impact | ROI Timeline |

|---|---|---|

| Concept | Low | N/A |

| Mold Fabrication | $5k-$10k | 1-2 Years |

| Beta Testing | Medium | 6 Months |

Mold fabrication and iterative testing represent the largest upfront capital risks, which must be amortized across the first production run.

Do Specialized Features Really Improve Performance?

Marketing departments love to highlight features, but technologies like aerodynamic throats and 3D textured surfaces on a pickleball paddle add legitimate manufacturing hurdles that increase the bill. These are not just stickers; they are structural modifications that require specialized tooling and longer cycle times.

Performance Metrics vs Manufacturing Effort

Ready for the truth? Achieving a high RPM spin rate requires a peel-ply texture that must be applied perfectly to avoid USAPA disqualification. Every feature that reduces drag or increases spin adds a step to the assembly line, increasing the chance of error.

- Aerodynamics: Open throats require complex, multi-part molds.

- Grit Application: 3D textures need precise curing times.

- Vibration Dampening: Internal silicone gel adds material cost.

Key Takeaway: Feature-Benefit Analysis

Features drive sales, but they also drive complexity.

| Feature | Complexity | Benefit |

|---|---|---|

| Aero Throat | High | Swing Speed |

| Raw Carbon | Medium | High Spin |

| Foam Walls | High | Sweet Spot |

Foam injection adds stability but requires precise timing during curing, making it one of the most expensive features to implement correctly.

Why Does USAPA Approval Spike Pickleball Paddle Prices?

A pickleball paddle is effectively useless for tournament play without the USAPA stamp, but obtaining this certification is a costly bureaucratic hurdle. Manufacturers must pay significant fees for testing, and if a paddle fails a deflection or roughness test, the cost doubles as they must re-engineer and re-submit.

The Cost of Compliance Testing

Here is the kicker: the testing process is rigorous and unforgiving. Brands must pay for the lab time, the certification listing, and the annual renewal fees to keep their paddle on the approved list, all of which is baked into the unit cost.

- Submission Fees: Thousands of dollars per model.

- Re-testing: Failure requires a complete financial restart.

- Sample Shipping: Dozens of units are sacrificed for the lab.

Key Takeaway: The Certification Tax

Approval is a mandatory fixed cost for legitimate gear.

| Step | Cost Factor | Risk |

|---|---|---|

| Initial Fee | High | Low |

| Lab Testing | Moderate | High (Fail) |

| Re-submission | High (Double) | Medium |

A single failure in the lab can delay a launch by months and double the certification budget, forcing brands to price in this risk premium.

How Do Brand Reputations Affect Pickleball Paddle Costs?

When you purchase a pickleball paddle from a major brand, you are paying for the quality assurance and customer support infrastructure that generic factories simply do not provide. Large brands invest heavily in inspection teams to ensure that the paddle you receive matches the specs of the one you saw online.

Marketing vs Manufacturing Costs

Let’s be real for a second, a factory-direct paddle might look similar, but who do you call when the core crushes in a week? Brands absorb the costs of sponsorship deals, professional photography, and warehousing to ensure a consistent customer experience.

- QA Checks: Removing defective units before shipping.

- Support Teams: Real humans handling inquiries.

- Sponsorships: Paying pros to validate the gear.

Key Takeaway: The Brand Premium

Reputation protects the buyer’s investment through consistency.

| Cost Driver | Generic | Brand Name |

|---|---|---|

| Making | $30 | $40 (QC) |

| Marketing | $0 | $50+ |

| Support | $0 | $20 |

Marketing and sponsorship costs often exceed the actual manufacturing cost for major brands, creating the large gap between factory cost and MSRP.

How Does Customization Impact Pickleball Paddle Rates?

Standardization is the friend of affordability, while requesting a custom pickleball paddle destroys economies of scale and sends labor costs skyrocketing. Stopping a high-speed production line to print a specific graphic or adjust a grip size for a small batch requires manual intervention that factories charge a premium for.

Small Batch vs Mass Production

Think about it: setting up a UV printer for one unique design takes the same time as setting it up for a thousand. Custom orders often require digital printing rather than water transfer, which is slower and more expensive per unit.

- Setup Time: Machines must be recalibrated.

- Design Proofing: Humans must verify art files.

- Waste: Custom errors cannot be resold.

Key Takeaway: The Customization Surcharge

Uniqueness requires expensive manual labor.

| Process | Mass Run | Custom Run |

|---|---|---|

| Setup | Amortized | High Cost |

| Method | Fast Transfer | Slow Print |

| Labor | Optimized | Manual |

Customization shifts the cost structure from material-dominant to labor-dominant, often increasing the unit cost by 50-100%.

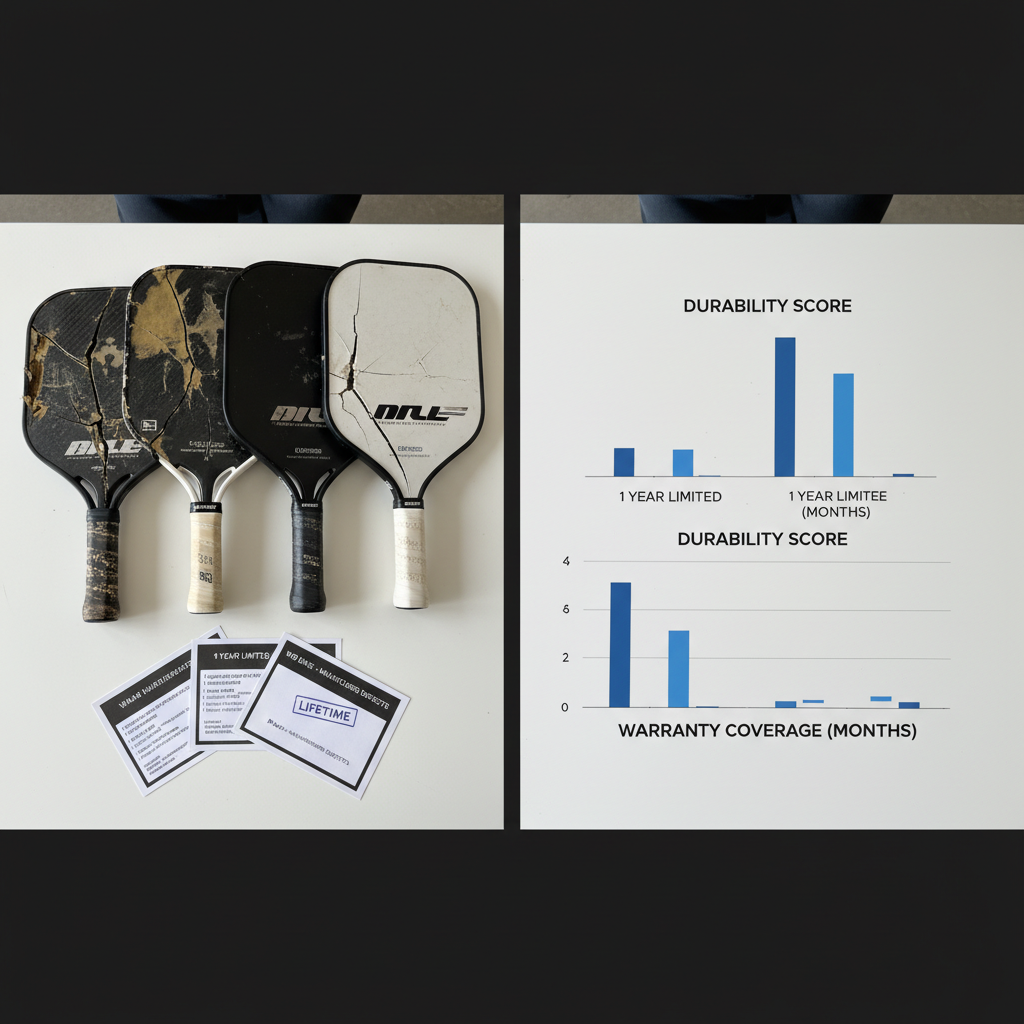

What Warranty Protections Justify Pickleball Paddle Fees?

A significant slice of the price you pay for a premium pickleball paddle is actually a prepaid insurance policy against structural failure. Brands that offer six-month or lifetime warranties must mathematically account for a percentage of returns, pricing their gear higher to create a reserve fund.

Risk Management in Pricing

You might not know this, but high-performance gear often lives on the edge of failure to maximize pop. Manufacturers calculate the “fail rate” and build the cost of replacement shipping and inventory into the initial price tag.

- Reserve Funds: Money set aside for claims.

- Reverse Logistics: Cost of processing returns.

- No-Questions Policies: Premium service costs premium money.

Key Takeaway: The Hidden Insurance

You pay for the guarantee of longevity.

| Warranty | Price Impact | Benefit |

|---|---|---|

| None | Low | High Risk |

| 6 Months | Medium | Standard |

| Lifetime | High | Peace of Mind |

Brands with generous warranty policies must price their products 15-20% higher to maintain profitability against inevitable claims.

Is the Investment in High-End Paddles Worth It?

After dissecting the costs, the ultimate question is whether the performance of an expensive pickleball paddle translates to winning more points. For the beginner, a fiberglass paddle is sufficient, but for the player facing 50 mph drives, the stability and consistency of high-end carbon are non-negotiable.

Performance and Playability

It boils down to this: cheap paddles flutter and twist on off-center hits, causing errors. A high-end paddle with high twist weight and a large sweet spot corrects your mistakes, keeping the ball in play when your mechanics aren’t perfect.

- Sweet Spot: Significantly larger on pro paddles.

- Vibration: Reduced risk of tennis elbow.

- Consistency: The ball reacts predictably every time.

Key Takeaway: ROI for the Player

Value is determined by usage frequency and competitive drive.

| Level | Paddle Tier | Lifespan |

|---|---|---|

| Novice | Fiberglass | 1 Year |

| Intermediate | Hybrid | 18 Months |

| Pro | Raw Carbon | 6-9 Months |

While pro paddles are expensive, they provide technical advantages like spin and dwell time that cheap fiberglass paddles simply cannot physically generate.

Conclusion

The sticker shock of a modern pickleball paddle is not arbitrary; it is the calculated result of using aerospace T700 carbon, implementing slow-bake thermoforming processes, and navigating the expensive USAPA certification landscape. You are not just paying for a brand name; you are paying for the R&D that expanded the sweet spot and the warranty that protects your purchase.

If you are ready to equip your business or your game with gear that justifies every cent of its cost through performance and durability, we are here to help. Contact us today to explore our premium line of engineering-led pickleball equipment.

FAQ

Do expensive paddles really last longer than cheap ones?

Generally, yes. High-end paddles utilize resilient materials like carbon fiber and Kevlar combined with thermoformed bonding, which resists core crushing and dead spots significantly longer than the glued layers found in budget fiberglass or wood paddles.

Can I get a good paddle without spending $200?

Yes, for recreational play. You can find excellent intermediate paddles in the $100 range that offer a balance of power and control, but they may lack the advanced spin textures and vibration dampening systems found in top-tier professional models.

How do I know if a paddle is USAPA approved?

You should look for the USAPA approval seal printed directly on the paddle face. Additionally, you can verify the specific model on the official USAPA equipment list online to ensure it is legal for tournament play.

What is the biggest factor driving up paddle costs recently?

The shift toward thermoformed unibody construction is the primary driver. This manufacturing process takes much longer and has a higher defect rate than traditional cold pressing, forcing manufacturers to increase prices to cover labor and material waste.

Is a carbon fiber paddle better than fiberglass?

For most competitive players, yes. Carbon fiber is stiffer and offers a true, consistent response with a larger sweet spot, whereas fiberglass is softer and provides more “pop” but can feel inconsistent and vibrate more on off-center hits.