About Us – Top 1 Pickleball Paddles in Shenzhen

Who Trust in Us

For Clients

Lingzhuo Carbon Fiber Co., Ltd Factory

Who We Are

Lingzhuo Carbon Fiber Co., Ltd is a dedicated pickleball factory, not a general sports trading company. Every day, our engineers and quality team work on one thing: ensuring every paddle is what you want.

Our Growth

Founded in 2018, focused solely on pickleball, BSCI and ISO9001 certified manufacturing systems USAPA-approved paddle models available for your line. In-house teams for R&D, sampling, printing and assembly.

Win-win Cooperation

You share specific requirements, market positioning, and budget. We translate that into real paddles you can hold, test with our quality inspector, and ship to you.

OUR Advantage

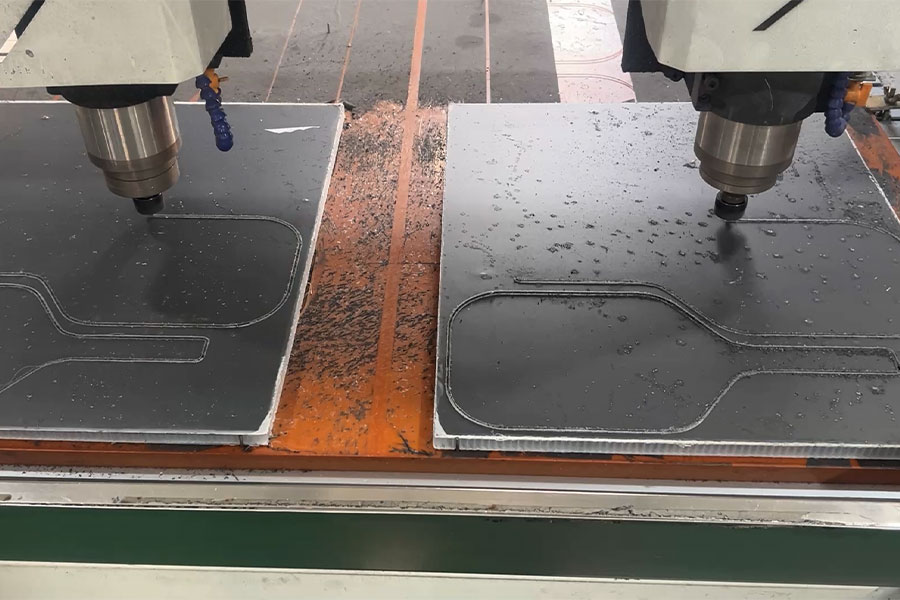

Pickleball Factory – Innovation in Printing

We design and manufacture paddles, balls, nets, and accessories under BSCI and ISO9001 certified systems. From thermoformed and edgeless paddles to Kevlar, titanium, and 3D 18K carbon fiber designs, we help you build a clear, well-positioned product line for your target players.

As a strength manufacturer, we have rich public molds to help you save on tooling costs. With USAPA-approved models and strict testing, your paddles are ready for serious play and a fast market launch.

OUR Advantage

Lingzhuo Carbon Fiber Co., Ltd Manufacturer

Emerging and established pickleball paddle brands Retail chains and online sports stores Importers and wholesalers focusing on racket sports Schools, clubs and training academies

Our product range is built to cover different playing styles, price points and brand positions. You can mix and match structures, faces and cores to design your own ladder of products.

Manufacturing Process

Why Brands Choose Our Factory

● Pickleball-only focus – All engineering and investment goes into this sport.

● Complete materials library – Carbon, Kevlar, titanium, TruFoam and multiple core options.

●Transparent communication – Clear feedback on feasibility, cost and timeline.

●Stable quality control – BSCI / ISO9001 systems and USAPA-approved constructions.

● Support for different brand stages – From small first runs to large, repeat orders.

At Lingzhuo Carbon Fiber Co., Ltd, We Support You With

Brand-specific mold options – Shape, edge profile and handle specifications tailored to you.

New material combinations – TruFoam cores, 3D 18K carbon faces, hybrid Kevlar/carbon stacks.

Performance tuning – Adjust stiffness, dwell time, sweet spot and swing weight to match your player profile.

You can bring your own ready artwork, or share your brand style and let our team help you adapt designs to real production files.